Ignite Black Ops Airsoft M4 Electric Blowback Gun

Ignite Black Ops Airsoft M4 Electric Blowback Gun

Blowback is a system of operation for self-loading firearms that obtains energy from the move of the cartridge example equally it is pushed to the rear by expanding gas created past the ignition of the propellant charge.[1]

Several blowback systems exist within this broad principle of functioning, each distinguished by the methods used to command bolt movement. In most actions that apply blowback operation, the breech is not locked mechanically at the time of firing: the inertia of the commodities and recoil spring(s), relative to the weight of the bullet, delay opening of the breech until the bullet has left the barrel.[ii] A few locked breech designs use a grade of blowback (example: primer actuation) to perform the unlocking role.

The blowback principle may be considered a simplified form of gas operation, since the cartridge case behaves like a piston driven by the pulverisation gases.[ane] Other operating principles for cocky-loading firearms include delayed blowback, blow forward, gas functioning, and recoil functioning.

Principle of operation [edit]

In firearms, a blowback system is generally defined as an operating system in which free energy to operate the firearm's various mechanisms, and automate the loading of another cartridge, is derived from the inertia of the spent cartridge case being pushed out the rear of the chamber past quickly expanding gases produced by a burning propellant, typically gunpowder.[3] When a projectile (east.g. bullet) is still within the gun butt, the high-force per unit area propellant gas behind it is contained within what could exist seen every bit a airtight organisation; simply at the moment it exits the muzzle, this functional seal is broken, allowing the propellant gas to be suddenly released in an explosive muzzle blast. The expanding gas also creates a jet propulsion upshot rearward in the butt against the spent cartridge case. This "blowback" is the predominant component of the recoil.[3] Some guns use energy from blowback to perform the autonomic commodities cycling /reloading procedure, while others will use a portion of the blowback to operate merely sure parts of the cycle or just apply the blowback energy to raise the operational energy from another system of automatic operation.[3]

What is mutual to all blowback systems is that the cartridge case must move under the direct action of the powder pressure level, therefore any gun in which the bolt is non rigidly locked, and permitted to movement while there remains gas pressure in the chamber, will undergo a caste of blowback activeness.[iii] The energy from the expansion of gases upon firing appears in the form of kinetic energy transmitted to the bolt mechanism, which is controlled and used to operate the firearm's operation cycle. The extent to which blowback is employed largely depends on the way used to command the motion of the bolt and the proportion of energy drawn from other systems of operation.[1] How the movement of the commodities is controlled is where blowback systems differ. Blowback performance is about ofttimes divided into three categories, all using residual pressure to consummate the cycle of operation: unproblematic blowback (oft just "blowback"), delayed/retarded blowback, and advanced primer ignition.

Relating blowback to other types of automatic firearm operation, George M. Chinn wrote that: "In the larger sense, blowback might well be considered a special course of gas operation. This is reasonable considering the cartridge example may exist conceived of as a sort of piston driven past the powder gases. Actually, blowback involves so many special problems that it is best considered to be in a class past itself. The question whether or not it should be included within the more than general class of gas performance or recoil operation is purely bookish. The important point is that it partakes some of the properties of both classes and, depending on the particular trouble at mitt, may exist considered to exist either 1."[1]

Uncomplicated blowback [edit]

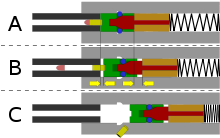

Blitheness of simple blowback operation

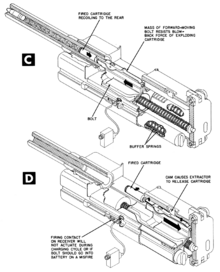

The blowback (sometimes referred to as "elementary", "direct" or "pure" blowback) system represents the most bones auto loading operation type. In a blowback mechanism, the bolt rests against the rear of the barrel, simply is not locked in identify. At the point of ignition, expanding gases push the bullet frontward through the barrel while at the same fourth dimension pushing the case rearward against the commodities. The expanding gases push the commodities assembly to the rear, but the motion is slowed by the mass of the commodities, internal friction, and the strength required to compress the action spring. The design must ensure that the delay is long enough that the bullet exits the barrel before the cartridge case clears the chamber. The empty case is ejected as the bolt travels to the rear. The stored energy of the compressed action bound so drives the commodities forrard (although not until the trigger is pulled if the weapon fires from an open up bolt). A new cartridge is stripped from the mag and chambered as the commodities returns to its in-battery position.

The blowback system is practical for firearms using relatively low-power cartridges with lighter weight bullets. Higher power cartridges require heavier bolts to go along the breech from opening prematurely; at some point, the commodities becomes also heavy to exist practical. For an extreme example, a xx mm cannon using simple blowback and lubricated cartridges would need a 500-pound (230 kg) commodities to keep the cartridge safely in the barrel during the first few milliseconds; furthermore, the average force supplied by the return spring is express to sixty pounds-force (270 N) or the bolt will not travel dorsum far plenty to feed a new round. Consequently, the return spring is not powerful plenty to continue the bolt airtight when the gun is tilted upwardly. In addition, there is not enough energy stored in the commodities to bicycle the weapon.[four]

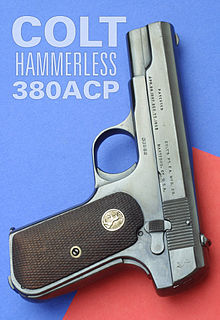

Due to the required bolt weight, blowback designs in pistols are generally limited to calibers smaller than ix×19mm Parabellum (due east.thousand., .25 ACP, .32 ACP, .380 ACP, 9×18mm Makarov, etc.) There are exceptions such as the uncomplicated blowback pistols from Howdy-Point Firearms which include models chambered in .40 S&W and .45 ACP.[5] Uncomplicated blowback operation can also be found in pocket-size-bore (such as .22LR) semi-automatic rifles, carbines and submachine guns. Virtually unproblematic blowback rifles are chambered for the .22 Long Burglarize cartridge. Popular examples include the Marlin Model 60 and the Ruger 10/22. Most blowback carbines and submachine guns are chambered for pistol cartridges such every bit the ix×19mm Parabellum, .forty S&Due west and .45 ACP. Examples include the MP twoscore, Sten and UZI. The bolt can exist made bigger and more massive in these weapons than in handguns, as they are intrinsically heavier and designed, ideally at least, to be fired with both hands, often with the aid of a shoulder stock; and these factors help to ameliorate the disruption to the shooter'due south aim caused by the heavy bolt's movement. Consequently, simple blowback is acceptable for somewhat more than powerful rounds in submachine guns than in standard pistols. In that location were also a few rifles that chambered cartridges specifically designed for blowback operation. Examples include the Winchester Model 1905, 1907 and 1910. The only known assault burglarize to employ simple blowback was the Burton Model 1917.[half-dozen]

Whereas simple blowback is express to guns using low-ability rounds, information technology is so efficient in this context that in small-calibre semi-automatic pistols it is by at present nigh ubiquitous. Heavier calibre semiautomatic handguns typically utilise a brusk recoil system, of which past far the about mutual type are Browning-derived designs which rely on a locking barrel and slide associates instead of blowback. Merely blowback guns tin be used to fire powerful cartridges if they are of the other 2 types already mentioned: API or delayed blowback.

Avant-garde primer ignition (API) blowback [edit]

In the API blowback pattern, the primer is ignited when the bolt is still moving frontward and before the cartridge is fully chambered (alike to the fire-out-of-bombardment principle used in some mountain guns like Canon de 65 M (montagne) modele 1906, although there the bolt is locked and whole ordnance is moving at burn down). This requires a very careful design to ensure the proper residue and equalization of forces betwixt the projectile weight, propellant charge, barrel length, bolt weight, and return leap strength. In a simple blowback pattern, the propellant gases have to overcome static inertia to accelerate the bolt rearwards to open the breech. In an API blowback, they first take to do the work of overcoming forward momentum to abort the frontward motion of the bolt. Because the forrad and rearward speeds of the bolt tend to exist approximately the same, the API blowback allows the weight of the bolt to be halved.[7] Because the momentum of the 2 opposed bolt motions cancels out over time, the API blowback design results in reduced recoil.

According to Anthony G. Williams, the "API blowback principle is used virtually in all open bolt sub-machine guns" (technically, although generally these are known as "simple blowback" weapons due to the very late ignition of the cartridge compared to specially designed API blowback guns like the MK 108), although "the relatively low pressures and velocities mean that extended chambers and rebated-rim cartridges are non required" for sub-machine guns.[8] An example of API in sub-automobile guns is the L2A3 Sterling submachine gun, where the maximum bedroom pressure level is achieved while the breechblock is still moving forward and is about 0.46 mm away from the rear face of the chamber.[9]

In heavier weapons, avant-garde primer ignition (API) was originally developed by Reinhold Becker[10] for use on the Becker Type M2 20 mm cannon. It became a characteristic of a wide range of designs that tin can exist traced back to Becker's, including the Oerlikon cannon widely used every bit anti-aircraft weapons during Globe War Two.[8]

To increment functioning of API blowback firearms,[vii] larger calibre APIB guns such as the Becker and Oerlikon use extended chambers, longer than is necessary to contain the round, and armament for APIB firearms come with direct-sided cartridges with rebated rims (rims that are smaller in diameter than the cartridge itself).[11] The last part of forward motion and the starting time part of the rearward motion of the case and bolt happen within the confines of this extended bedchamber. Equally long every bit the gas pressure in the barrel is high, the walls of the example remain supported and the breach sealed, although the example is sliding rearwards. This sliding motion of the case, while it is expanded past a high internal gas pressure, risks tearing it apart, and a common solution is to grease the ammunition to reduce the friction. The example needs to take a rebated rim because the front end terminate of the bolt volition enter the chamber, and the extractor claw hooked over the rim therefore has to fit also within the diameter of the sleeping room. The case generally has very fiddling neck, because this remains unsupported during the firing cycle and is generally deformed; a strongly necked example would be probable to split up.

The API blowback pattern permits the use of more than powerful armament in a lighter gun than would exist accomplished by using simple blowback, and the reduction of felt recoil results in further weight savings. The original Becker cannon, firing twenty×70mmRB armament, was developed to be carried by Earth State of war I aircraft, and weighed only thirty kg.[12] Oerlikon even produced an anti-tank rifle firing xx×110mmRB armament using the API blowback operation, the SSG36. On the other hand, considering the design imposes a very close relationship between bolt mass, bedchamber length, spring strength, armament power and rate of fire, in APIB guns high charge per unit of fire and high cage velocity tend to be mutually exclusive.[eleven] API blowback guns likewise have to burn down from an open bolt, which is non conducive to accurateness and as well prevents synchronized fire through an aircraft propeller arc.

Co-ordinate to a Usa Ground forces Materiel Command engineering form from 1970, "The advanced primer ignition gun is superior to the simple blowback because of its higher firing rate and lower recoil momentum. All the same, favorable performance depends on timing that must be precise. A slight delay in primer function, and the gun reverts to a simple blowback without the benefit of a massive commodities and stiffer driving spring to soften the recoil touch on. [...] The exacting requirements in pattern and construction of gun and ammunition reduce this type virtually to the point of academic interest merely."[13]

API mechanisms are very sensitive to the ammunition used. For case, when the Germans switched their MG FF (an Oerlikon FFF derivative) to their new, lighter mine shell, they had to rebalance the spring strength and bolt weight of the gun, resulting in a new MG FF/1000 model with armament not existence interchangeable between the two models.[fourteen] The xxx mm MK 108 cannon was perhaps the apogee of API blowback technology during Earth War II.

The principle is also used in some automated grenade launchers, for example in the Us Mk 19 grenade launcher or Russian AGS-30.

Delayed blowback [edit]

For more powerful rounds that cannot be safely used in uncomplicated blowback, or in order to obtain a lighter mechanism than the unproblematic format can provide, the alternative to API is some organisation of delayed or retarded blowback, in which the bolt is never fully locked, but is initially held in place, sealing the cartridge in the chamber by the mechanical resistance of 1 of various designs of delaying mechanism. As with the resistance provided past momentum in API, it takes a fraction of a second for the propellant gases to overcome this and start moving cartridge and bolt backwards; this very cursory delay is sufficient for the bullet to leave the muzzle and for the internal pressure in the butt to decrease to a safe level. The bolt and cartridge are then pushed to the rear by the residue gas pressure.

Because of high pressures, rifle-caliber delayed blowback firearms, such as the FAMAS and G3, typically have fluted chambers to ease extraction. Below are various forms of delayed-blowback actions:

Roller-delayed [edit]

Roller-delayed blowback-operated breech for automated weapons

A schematic of the G3 roller-delayed blowback machinery

Cutaway model of the chamber with gas relief flutes (left) and roller-delayed activeness of the G3 battle burglarize

Roller-delayed blowback was first used in Mauser'southward Gerät 06H prototype. Roller-delayed blowback performance differs from roller-locked recoil operation equally seen in the MG 42 and gas operated roller locked, as seen in the Gerät 03 and Gerät 06.[15] Dissimilar the MG 42, in roller-delayed blowback the butt is stock-still and does not recoil, and unlike the Gerät 03 and Gerät 06 and StG 44, roller-delayed blowback systems lack a gas piston. These omissions are conducive to relatively lite construction by significantly reducing the number of parts required and the amount of machining required to produce a rifle. As the bolt head is driven rearward, rollers on the sides of the bolt are driven inward confronting a tapered bolt carrier extension. This forces the bolt carrier rearward at a much greater velocity and delays movement of the commodities head. The primary reward of roller-delayed blowback is the simplicity of the design compared to gas or recoil operation.[sixteen]

The roller-delayed blowback firearm action was patented by Mauser's Wilhelm Stähle and Ludwig Vorgrimler. Though actualization simple its evolution during World State of war II was a hard technical and personal effort, equally German engineering, mathematical and other scientists had to work together on a similar-it-or-not basis led by Ott-Helmuth von Lossnitzer, the director of Mauser Werke's Weapons Research Establish and Weapons Evolution Grouping. Experiments showed roller-delayed blowback firearms exhibited commodities-bounce as the commodities opened at an extreme velocity of approximately 20 m/s (66 ft/due south) during automatic burn down. To counter bolt-bounce the perfect bending selection on the olfactory organ of the bolt caput had to be establish to significantly reduce the opening velocity of the commodities. The extremely high bolt carrier velocities trouble was not solved by trial and error. Mathematician Karl Maier provided analysis of the components and assemblies in the development project.[17] In December 1943 Maier came up with an equation that engineers used to change the angles in the receiver to 45° and 27° on the locking piece relative to the longitudinal axis reducing the bolt-bounciness problem. With these angles the geometrical transmission ratio of the commodities carrier to the bolthead became 3:i, so the rear bolt carrier was forced to motility 3 times faster than the bolthead. The rearward forces on the bolt carrier and receiver were 2:one. The force and impulse transmitted to the receiver increases with the strength and impulse transmitted to the commodities carrier. Making the commodities carrier heavier lessens the recoil velocity. For Mausers StG 45(M) project Maier assumed a 120 g (4.2 oz) commodities head and 360 g (12.7 oz) bolt carrier (1 to 3 ratio). The image StG 45 (K) set on burglarize had 18 longitudinal gas relief flutes cutting in the chamber wall to aid the swollen cartridge casing from the chamber walls during extraction. Fluting the stop of the chamber provides pressure equalization between the front outer surface of the cartridge case and its interior and thus ensures extraction without tearing the case making extraction easier and more reliable. In 1944 other German companies like Großfuß (de), Rheinmetall and C.G. Haenel showed interest in developing roller-delayed blowback small arms. Großfuß worked on a roller-delayed blowback MG 45 general-purpose car gun that, like the StG 45 (M), had not progressed across the epitome phase by the cease of World State of war II.

After World State of war Two, former Mauser engineers Ludwig Vorgrimler and Theodor Löffler perfected the mechanism between 1946 and 1950 while working for the French minor arms manufacturer Heart d'Etudes et d'Armament de Mulhouse (CEAM). In 1950 Ludwig Vorgrimler was recruited to work for CETME in Espana. The first full-scale production rifle to utilize roller-delay was the Spanish CETME boxing rifle, which was closely followed past the Swiss SIG SG 510 and the CETME Model B-based Heckler & Koch G3. The G3 bolt features an anti-bounce machinery that prevents the bolt from billowy off the butt's breech surface.[18] The G3'southward "bolt caput locking lever" is a spring-loaded claw mounted on the bolt carrier that grabs the bolt head as the bolt carrier group goes into battery. The lever essentially ratchets into identify with friction, providing enough resistance to beingness re-opened that the bolt carrier does not rebound. Due to the relative low bolt thrust exhibited by pistol cartridges the anti-bounce machinery is omitted past Heckler & Koch on their roller-delayed blowback firearms chambered for pistols cartridges. Heckler & Koch's MP5 submachine gun is the near common weapon still in service worldwide using this system. The Heckler & Koch P9 semi-automated pistol, CETME Ameli light machine gun and Heckler & Koch HK21 general-purpose machine gun also use it.

Roller-delayed blowback arms are ammunition specific, since they lack an adjustable gas port or valve to arrange the arm to various propellant and projectile specific pressure behavior. Their reliable functioning is limited by specific armament and arm parameters like bullet weight, propellant accuse, barrel length and corporeality of habiliment. At the moment of cartridge ignition the chamber has to be and remain sealed, until the bullet has exited the barrel and the gas pressure inside the bore has dropped to a safe level earlier the seal is cleaved and chamber starts to open. For obtaining a proper and condom functioning parameters bandwidth arms articles offer a variety of locking pieces with different mass and shoulder angles and cylindrical rollers with different diameters. The angles are critical and determine the unlock timing and gas pressure drib direction equally the locking piece acts in unison with the commodities caput carrier. The bolt gap width determines the headspace and hence the correct positioning of the cartridges in the (closed) sleeping accommodation. Due to usage habiliment the bolt gap betwixt the locking slice and bolt head carrier is expected to gradually increase. It tin can be determined and checked by a feeler guess measurement and can be contradistinct by changing the cylindrical rollers for rollers with a different bore. Installing larger bore rollers volition increase the bolt gap and push the locking slice forward. Installing smaller diameter rollers results in the opposite effects.[19] [xx] [21]

Lever-delayed [edit]

A schematic of the lever-delayed blowback mechanism used in the FAMAS set on rifle.

Lever-delayed blowback utilizes leverage to put the commodities at a mechanical disadvantage, delaying the opening of the breech. When the cartridge pushes confronting the bolt face up, the lever moves the bolt carrier rearward at an accelerated rate relative to the calorie-free commodities. Leverage can exist applied with a defended part or through inclined surfaces interacting with each other. This leverage significantly increases resistance and slows the move of the lightweight bolt. The reliable functioning of lever-delayed blowback arms is express by specific armament and arm parameters similar bullet weight, propellant charge, butt length and amount of wear. John Pedersen patented one of the beginning known designs for a lever-delay arrangement.[22] The mechanism was too used by Hungarian artillery designer Pál Király in the 1910s and 1930s and used in the Danuvia 39M and 43M submachine guns for the Hungarian Ground forces.[23] After Earth War Two, Király settled in the Dominican Republic and developed the Cristóbal Carbine (or Király-Cristóbal Carbine) employing a similar mechanism. Other weapons to use this system are the Hogue Avenger and Benelli B76 pistols, the FNAB-43 submachine gun, the TKB-517, VAHAN and FAMAS[24] assault rifles, the Sterling 7.62 and AVB-vii.62 battle rifles/light car guns, and the AA-52 general-purpose machine gun.[25]

Gas-delayed [edit]

Gas-delayed blowback should not exist dislocated with gas-functioning. The bolt is never locked, and and then is pushed rearward by the expanding propellant gases, as in other blowback-based designs. All the same, propellant gases are vented from the butt into a cylinder with a piston that delays the opening of the commodities. It was used past some Earth State of war II German designs for the 7.92×33mm Kurz cartridge, including the Volkssturmgewehr burglarize (with little effectiveness) and the Grossfuss Sturmgewehr (with slightly more efficiency),[26] and after the war past the Heckler & Koch P7, Walther CCP, Steyr GB and Chiliad-77B pistols.

Chamber-band delayed [edit]

When a cartridge is fired, the case expands to seal the sides of the chamber. This seal prevents loftier-pressure gas from escaping into the action of the gun. Because a conventional chamber is slightly oversized, an unfired cartridge will enter freely. In a chamber-ring delayed firearm, the bedroom is conventional in every respect except for a concave ring within the chamber wall. When the cartridge is fired, the case expands into this recessed ring and pushes the commodities face rearward. Equally the case moves to the rear this ring constricts the expanded portion of the case. The energy required to clasp the walls of the cartridge example slows the rearward travel of the case and slide, reducing their mass requirements. The first known use of the arrangement was on the Fritz Mann pistol in 1920 and later the High Standard Corp model T3 experimental pistol developed by Ott-Helmuth von Lossnitzer while working for Loftier Standard.[27] [28] Other firearms that used this system were the LWS Seecamp pistol, the AMT Automag Ii, and the Kimball .30 Carbine pistol.[29] [xxx] [31] The SIG SG 510 rifle family incorporates a sleeping room ring near the shoulder which is used to avoid bolt-bounce rather than a filibuster element.[32]

Hesitation locked [edit]

John Pedersen's patented system incorporates a breech block independent of the slide or bolt carrier. When in bombardment, the breech cake rests slightly forward of the locking shoulder located in the frame of the firearm. When the cartridge is fired, the cartridge case, bolt and slide movement together a short distance until the breech block strikes the locking shoulder and stops. The slide continues rearward with the momentum it caused in the initial phase while the breech remains locked. This allows chamber pressure to drop to safe levels once the bullet departs the barrel. The standing motion of the slide lifts the breech block from its recess and pulls it rearward, continuing the firing bike. The Pedersen Remington Model 51 pistol, SIG MKMO submachine gun and R51 pistol are the but production firearms to have used this design.

Flywheel delayed blowback [edit]

Flywheel delayed blowback performance is where, during firing, the bolt opening is delayed past the rotational inertia of a flywheel. This is driven by a rack and pinion organisation on the bolt carrier. The Barnitzke, Kazachok SMG, MGD PM-9 uses this performance. Some other example would be the 3d printed burglarize under development by Evan Jones.

Toggle-delayed [edit]

Operation of the Schwarzlose machine gun.

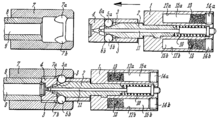

Image from Pedersen patent[33] describing toggle-delayed blowback mechanism as used in his rifle

In toggle-delayed blowback firearms, the rearward motion of the breechblock must overcome significant mechanical leverage.[34] [35] [36] The commodities is hinged in the eye, stationary at the rear end and nearly directly at rest. As the breech moves back under blowback ability, the swivel joint moves up.[37] The leverage disadvantage keeps the breech from opening until the bullet has left the barrel and pressures take dropped to a safety level. This mechanism was used on the Pedersen rifle and Schwarzlose MG M.07/12 machine gun.[35] [38]

Off-centrality bolt travel [edit]

John Browning developed this simple method whereby the centrality of bolt movement was not in line with that of the bore.[39] The outcome was that a small rearward move of the commodities in relation to the bore-axis required a greater movement along the axis of commodities movement, substantially magnifying the resistance of the bolt without increasing its mass. The French MAS-38 submachine gun of 1938 utilizes a commodities whose path of recoil is at an angle to the butt. The Jatimatic and KRISS Vector employ modified versions of this concept.

Radial-delayed [edit]

CMMG introduced the Mk 45 Guard rifle incorporating a radial-delay in 2017. This system uses the rotation of the bolt head to accelerate the commodities carrier of an AR-15 pattern rifle. The bolt locking lugs are adapted to incorporate 120° angles that rotate the bolt every bit it travels rearward nether conventional blowback ability. As the bolt rotates 22.5˚, it must accelerate the bolt carrier to the rear through an adapted fifty° angle cam-pin slot. This dispatch amplifies the constructive mass of the bolt carrier, slowing the speed of the bolt head.[40] This filibuster allows pressure to drib prior to extraction without the penalty of a heavier commodities carrier assembly.[41] The system is similar to roller and lever-delayed blowback in that it uses the mass of the bolt carrier moving at a faster rate than the commodities head to delay the action from opening. The design is described in U.S. Patent 10,436,530.

Spiral-delayed [edit]

First used on the Mannlicher Model 1893 automatic rifle, the bolt in screw-delayed blowback uses a plow bolt that was delayed past angled interrupted threads delayed by a quarter twist to unlock.[42] John T. Thompson designed an autorifle that operated on a similar principle around 1920 and submitted information technology for trials with the US Army. This rifle, submitted multiple times, competed unsuccessfully against the Pedersen rifle and Garand primer-actuated burglarize in early testing to supercede the M1903 Springfield rifle.[43] This operation is 1 of the most uncomplicated forms of delayed blowback but unless the ammunition is lubricated or uses a fluted sleeping accommodation, the recoil can be volatile especially when using total length rifle rounds.[44] Rotation of the bolt should be at to the lowest degree 90° to prevent ruptured cartridges.[45] Another course of this operation using a helical screw to delay rearward motion was the Salvator-Dormus M1893 machine gun and later the prototype Kalashnikov Model 1942 submachine gun in 1942[46] and the Fox Wasp carbine.

Other blowback systems [edit]

Floating chamber [edit]

David Marshall Williams (a noted designer for the U.South. Ordnance Office and later Winchester) developed a mechanism to allow firearms designed for full-sized cartridges to fire .22 caliber rimfire armament reliably. His system used a minor "piston" that incorporates the chamber. When the cartridge is fired, the front end of the floating chamber is thrust back by gas pressure impinging on the front of the chamber as in a traditional piston. This, added to the blowback energy imparted on the cartridge, pushes the bolt back with greater energy than either force alone. Often described as "accelerated blowback", this amplifies the otherwise anemic recoil energy of the .22 Rimfire cartridge.[47] Williams designed a training version of the Browning car gun and the Filly Service Ace .22 long rifle version of the M1911 using his system. The increased recoil produced past the floating chamber made these training guns behave more like their full-ability counterparts while still using inexpensive low-power ammunition. The floating bedchamber is both a blowback and gas operated mechanism.[48]

Primer actuated [edit]

Primer actuated firearms use the energy of primer setback to unlock and cycle the firearm. John Garand developed the system in an unsuccessful bid to replace the M1903 commodities-action rifle in the early on 1920s.[49] Garand'due south prototypes worked well with US armed forces .30-06 ammunition and uncrimped primers, but then the military changed from a fast burning gunpowder to a progressive burning Improved Military Rifle (IMR) powder. The slower pressure rise made the primer actuated prototypes unreliable, so Garand abased the design for a gas operated rifle that became the M1 Garand.[49] [fifty] AAI Corporation used a primer piston in a rifle submitted for the SPIW competition.[51] Other rifles to utilize this system were the Postnikov APT and Clarke carbine equally described in U.South. Patent ii,401,616.[52]

A like organization is used in the spotting rifles on the LAW 80 and Shoulder-launched Multipurpose Assault Weapon use a 9mm, .308 Winchester based cartridge with a .22 Hornet blank cartridge in identify of the primer. Upon firing, the Hornet example sets back a curt distance, unlocking the activity.[53]

Example setback [edit]

The case cartridge itself has been used experimentally to actuate the action similar to Garand's primer-actuation. Known prototypes using this method of operation include ii 1936 rifle designs, i past Mihail Mamontov and another by Makar Goryainov at TsKB-xiv, and a 1980s design by A.F. Barishev. The Mamontov and Goryainov rifles are only partially automatic; only the bolt unlocking is powered by the gases pushing the cartridge back, while the residual of the bike (ejection, reloading) is done manually as in a traditional bolt-activity rifle. A major problem with using the case cartridge as piston is that its motility is much faster (nearly ane ms) compared to borer gas further down the bore through a piston—virtually five ms in the Dragunov sniper burglarize, which used the same cartridge as Mamontov's burglarize. Barishev made a fully automatic, but rather beefy mechanism that used a mechanical delay. In his system, the case cartridge pushed back a tilting commodities face, that upon reaching a certain angle pushes backwards an unlocking lever that continues farther before unlocking the commodities. The GRAU even so still gave a negative evaluation of Barishev'due south gun, pointing out that the chief problems with reliability of firearms using the cartridge instance equally a piston were known since the 1930s and however unsolved.[54]

Limited-utility designs [edit]

Blish lock [edit]

The Blish Lock is a breech locking mechanism designed by John Bell Blish based upon his ascertainment that under extreme pressures, sure different metals will resist movement with a force greater than normal friction laws would predict. In modern engineering terminology, it is called static friction, or stiction. His locking mechanism was used in the Thompson submachine gun, Autorifle and Autocarbine designs. This dubious principle was afterward eliminated every bit redundant in the M1 and M1A1 versions of the submachine guns at the insistence of the The states Ground forces.[55] Lubrication or fouling would completely defeat whatever delay. Whatever actual advantage a make clean, unlubricated Blish arrangement could impart could likewise be attained by adding a mere ounce of mass to the bolt.[56]

Savage rotating butt [edit]

The Cruel system employed the theory that the rifling in the barrel acquired a rotational force that would hold the gun locked until the projectile left the butt. It was later discovered that the bullet had left the barrel long before whatever locking could occur. Savage pistols were in fact operating every bit elementary blow back firearms.[57] The French MAB PA-15 and PA-8 9mm pistols characteristic a similar design.

Headspace actuated unlocking [edit]

An unusual operation that uses a commodities head that moves rearwards when firing that allows the cartridge to motility backwards or even stretching it until the bolt unlocks. [58] [59] When firing the cartridge moves the bolt head rearwards around two.5mm until information technology stops, then rotates the bolt to unlock and cycle the performance.

Magnet delay [edit]

An operation using a "elementary blowback" type commodities that has neodymium magnets to delay its operation.[60] A special buffer using this operation has been developed by TACCOM.

Other autoloading systems [edit]

Other autoloading systems are:

- Blow forward where the barrel is the only moving component of the weapon that is dragged forward past the friction of the bullet until it leaves the barrel.

- Recoil operation uses the rearward move of parts of the weapon counter to the ejecta (bullet and propellant) moving frontward, equally described past Newton's third police of motion.

- Gas-operated reloading

Meet also [edit]

- List of blow forward firearms

- List of delayed-blowback firearms

- List of API blowback firearms

References [edit]

- ^ a b c d Chinn 1955, p. three

- ^ Walter H. B. Smith, Rifles, Military machine Service Publishing Co., 1948, "blowback semiautomatic performance" pp.88-89.

- ^ a b c d Chinn 1955, p. 11

- ^ Chinn 1955, pp. 12–16

- ^ "Hi-Point Firearms: Handguns". Hi-Signal Firearms. Archived from the original on 2011-07-eleven.

- ^ The World'south Assault Rifles By Gary Paul Johnston, Thomas B. Nelson. Chapter 2: Assault Rifle Operating and Locking Systems.

- ^ a b Chinn 1955, p. 31

- ^ a b Anthony G. Williams, Rapid Burn down, Airlife United kingdom of great britain and northern ireland 2000, page 65

- ^ Charles Q. Cutshaw (2011). Tactical Small Arms of the 21st Century: A Consummate Guide to Small Artillery From Around the World. Gun Digest Books. ISBN978-1-4402-2482-ix . Retrieved eight July 2013.

- ^ Williams, Anthony K., Of Oerlikons and other things…… Archived 2014-11-10 at the Wayback Machine world wide web.quarry.nildram.co.united kingdom of great britain and northern ireland article

- ^ a b Anthony G. Williams, Rapid Fire, Airlife UK 2000, pages 63-68

- ^ Anthony 1000. Williams, Flying Gun Earth War I, Airlife U.k. 2003, pages 89-90

- ^ Automated Weapons Archived 2013-08-01 at the Wayback Auto, AMC pamphlet no. 706-260, February 1970, folio 2-47

- ^ Anthony G. Williams, Rapid Fire, Airlife United kingdom of great britain and northern ireland 2000, pages 65 and 166

- ^ Forgotten Weapons (2012-11-nineteen), Last Ditch Innovation: The Development of the Gerat 06 and Gerat 06H Rifles, archived from the original on 2021-12-12, retrieved 2017-11-30

- ^ Stevens, R. Blake, Full Circle: A Treatise on Roller Locking, Collector Grade Publications (2006). ISBN 0-88935-400-six.

- ^ Practise You Know Your HK'south Parents?

- ^ Woźniak, Ryszard. Encyklopedia najnowszej broni palnej – tom 2 G-Ł. Bellona. 2001. pp. seven–10.

- ^ How Does Information technology Work: Roller Delayed Blowback

- ^ Deportment: Blowback Action: Roller Delayed Blowback

- ^ How Roller-Delayed Firearms Work and Why information technology Matters

- ^ U.S. Patent one,410,270

- ^ "Gun automatics: Delayed blowback activeness". 7 January 2018.

- ^ Popenker, Maxim (27 Oct 2010). "GIAT FAMAS assault rifle (France)". Modern Firearms. Archived from the original on 2017-06-fifteen. Retrieved 2017-06-26 .

- ^ French Patent FR949973A Mécanisme de retard à fifty'ouverture de culasse d'arme à feu, Published 1949-09-14

- ^ Пономарёв, Юрий (September 2006), история: малоизвестное оружие второй мировой войны: Автомат Хорна [History: a niggling-known weapon of World War 2: Horn Set on Burglarize] (PDF), КАЛАШНИКОВ. ОРУЖИЕ, БОЕПРИПАСЫ, СНАРЯЖЕНИЕ (Kalasnikov: Weapons, armament, equipment) (in Russian): 20–26, archived (PDF) from the original on 2014-04-08, retrieved 2013-08-17

- ^ "High Standard T3 Prototype: An American Blowback at James D Julia". five April 2017. Archived from the original on 2017-04-14. Retrieved 2017-04-13 .

- ^ "The Mann .25 Pistol". Archived from the original on 2018-03-xxx. Retrieved 2018-03-29 .

- ^ "50.W. Seecamp Co. - Care & Maintenance". Archived from the original on 2017-02-28. Retrieved 2017-02-27 .

- ^ "AMT Automag 2-V". 22 October 2010. Archived from the original on 2018-03-13. Retrieved 2018-03-29 .

- ^ "Detroit'due south Short-Lived Kimball .30 Carbine Pistol". 29 March 2018. Archived from the original on 2018-03-xxx. Retrieved 2018-03-29 .

- ^ "The SG510 Assault Rifle of Switzerland". Archived from the original on 2017-04-04. Retrieved 2017-02-23 .

- ^ U.S. Patent 1,737,974

- ^ Cliff Carlisle, Japanese Pedersen Semi Automobile Rifles & Carbines Archived 2007-08-19 at the Wayback Machine, www.carbinesforcollectors.com article

- ^ a b Marshall Cavendish Corporation (2003). How It Works: Science and Technology. Marshall Cavendish. p. 194. ISBN978-0-7614-7314-5. Archived from the original on 2017-03-28. Retrieved 2016-xi-02 .

- ^ Automatic Weapons Archived 2013-08-01 at the Wayback Machine, AMC pamphlet no. 706-260, February 1970, page 2-40

- ^ "Система запирания канала оружейных стволов Patent RU2529303". Archived from the original on 2018-x-08. Retrieved 2018-10-07 .

- ^ Hatcher, Julian, Hatcher's Notebook, The Military Service Press Company (1947), pp. 38-44. ISBN 0-8117-0795-4.

- ^ U.S. Patent 1,457,961

- ^ Radial delayed blowback operating system, such as for ar 15 platform US20180142972A1

- ^ "CMMG Mk45". Archived from the original on 2018-ten-08. Retrieved 2018-x-08 .

- ^ Repetier- und Automatische Handfeuer Waffen, Der systeme Ferdinand Ritter von Mannlicher

- ^ Hatcher, Julian (1983). Volume of the Garand. Gun Room Pr. ISBN0-88227-014-one.

- ^ Ordnance, The Thompson Autorifle Caliber .xxx past H. E. Hartney, 1921, P150

- ^ Ordnance, Volume 3-4, American Defence Preparedness Association 1922. THE PROBLEM OF AN INFANTRY RIFLE. Page 153

- ^ Ширяев, Д. (2000). "Кто изобрел автомат Калашникова" [Who invented the Kalashnikov?]. Солдат удачи (in Russian). ix (72).

- ^ "Charles E. Piddling, Delightful diversion, Guns Magazine, March, 2004". Archived from the original on 2007-09-02. Retrieved 2007-09-06 .

- ^ South. P. Fjestad (1991). Blue Book of Gun Values, 13th Ed. p. 291. ISBN0-9625943-4-2.

- ^ a b Julian South. Hatcher (1962). Hatcher's Notebook. Stackpole Books. pp. 63–66. ISBN978-0-8117-0795-iv. Archived from the original on 2017-02-28. Retrieved 2016-11-02 .

- ^ "Experimental semi-automatic rifles by John Garand, 1919-1936". National Park Service. Retrieved 2014-12-28 .

the primer actuated device was doomed to failure as the .30 caliber cartridge did not lend itself to this type of operation

- ^ Flirting With Flechettes: The U.s.a. Army's Search for the Ideal Rifle Projectile Archived 2007-09-27 at the Wayback Machine Cruffler.com May 2000 article

- ^ "Clarke carbine". 27 October 2010. Archived from the original on 2017-01-07. Retrieved 2017-03-13 .

- ^ "9 x 51mm SMAW - International Ammunition Association". Archived from the original on 2011-07-25. Retrieved 2008-06-30 .

- ^ Р. Чумак, ГИЛЬЗОВЫЙ ДВИГАТЕЛЬ. О необычных системах автоматики Archived May 13, 2014, at the Wayback Motorcar, Kalashnikov magazine 2012/11, pp. 72-77

- ^ Soviet Submachine Guns Of World War Ii. Chris McNab, Osprey Publishing,2014.

- ^ Army Ordnance, December 1920

- ^ Hatcher, Julian (1947), Hatchers Notebook, The Military machine Service Printing Visitor, pp. 259–261, ISBN0-8117-0795-4

- ^ "Firearm".

- ^ "Headspace-Operated Epitome Rifle – Yep, it'due south as Weird every bit information technology Sounds". 28 Dec 2020.

- ^ "TACCOM Delayed Blowback 9mm Recoil Organization with Neodymium Magnets -". two July 2019.

Bibliography [edit]

- Bremner, Derek, The MG42V and the Origins of Delayed Blowback Roller Lock: WWII German Equipment (Paperback). ISBN 0-9533792-0-5.

- Chinn, George Chiliad. (1955). The Machine Gun, Volume IV: Design Analysis of Automated Firing Mechanisms and Related Components. Washington, D.C.: Bureau of Ordnance, Department of the Navy.

External links [edit]

- How Does it Work: Blowback Action Forgotten Weapons

- How Does it Work: Gas-Delayed Blowback Forgotten Weapons

- How Does It Work: Lever Delayed Blowback Forgotten Weapons

- How Does It Work: Roller Delayed Blowback Forgotten Weapons

- How Does It Work: Toggle Actions Forgotten Weapons

- Radial Delayed Blowback

- Radial Delayed Blowback

- Data about the TZ45 submachine gun and the concept of advanced primer ignition

- Blowback activity, Animation and explanation at howstuffworks.com

- Heckler and Koch USA now uses the "roller-delayed blowback" terminology

- Blow-Forrard operated submachine gun patent

- Blow-Forward firearm patent

- Kewish primer actuated patent (ane/4 assigned to Garand)

- US1603684 Garand patent making reference to earlier primer actuated application in 1919.

- Burke v Us, 67 F.Supp 827 (1947) has annotate about Kewish and Garand.

- What Does Blowback Hateful In Airsoft?

Ignite Black Ops Airsoft M4 Electric Blowback Gun

Posted by: hoskinssompery.blogspot.com

0 Response to "Ignite Black Ops Airsoft M4 Electric Blowback Gun"

Post a Comment